A true revolution for industrial design

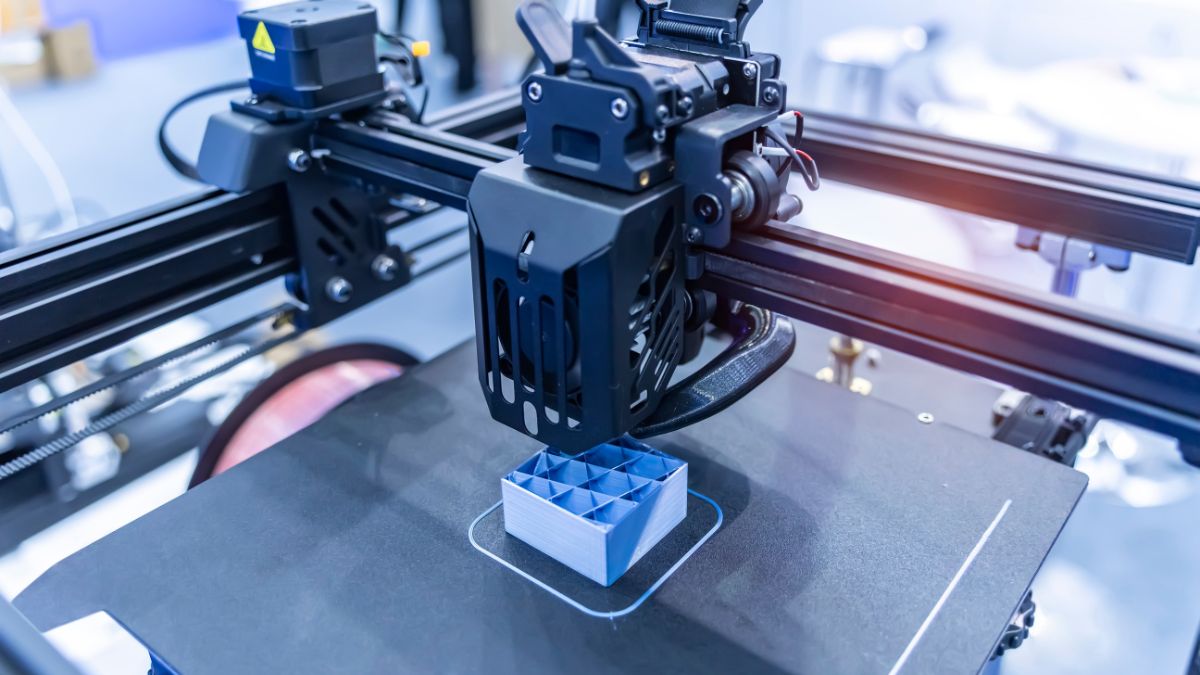

Rapid prototyping with 3D printing Rapid prototyping has revolutionized the way companies approach product development. This technology allows ideas to be transformed into physical models in a matter of hours, significantly accelerating the design and manufacturing process. In a world where agility is key to staying competitive, rapid prototyping has become an indispensable tool for sectors such as engineering, automotive, architecture, and industrial design.

Thanks to rapid prototyping with 3D printing, can be Create physical models from digital designs in a short period of time. This technology uses materials such as plastics, resins, and metals to build parts layer by layer, allowing designers and developers to visualize, test, and adjust their products more quickly and cost-effectively than with traditional methods such as machining or injection molding.

Main advantages of rapid prototyping with 3D printing

- Speed of development: Prototype manufacturing time is drastically reduced thanks to the ability to produce parts directly from CAD files. This facilitates iterative development, allowing multiple versions of the same design to be produced in a single day.

- Cost reduction: Because it doesn't require expensive molds or tools, rapid prototyping is especially useful in the early design phase, when multiple iterations are needed.

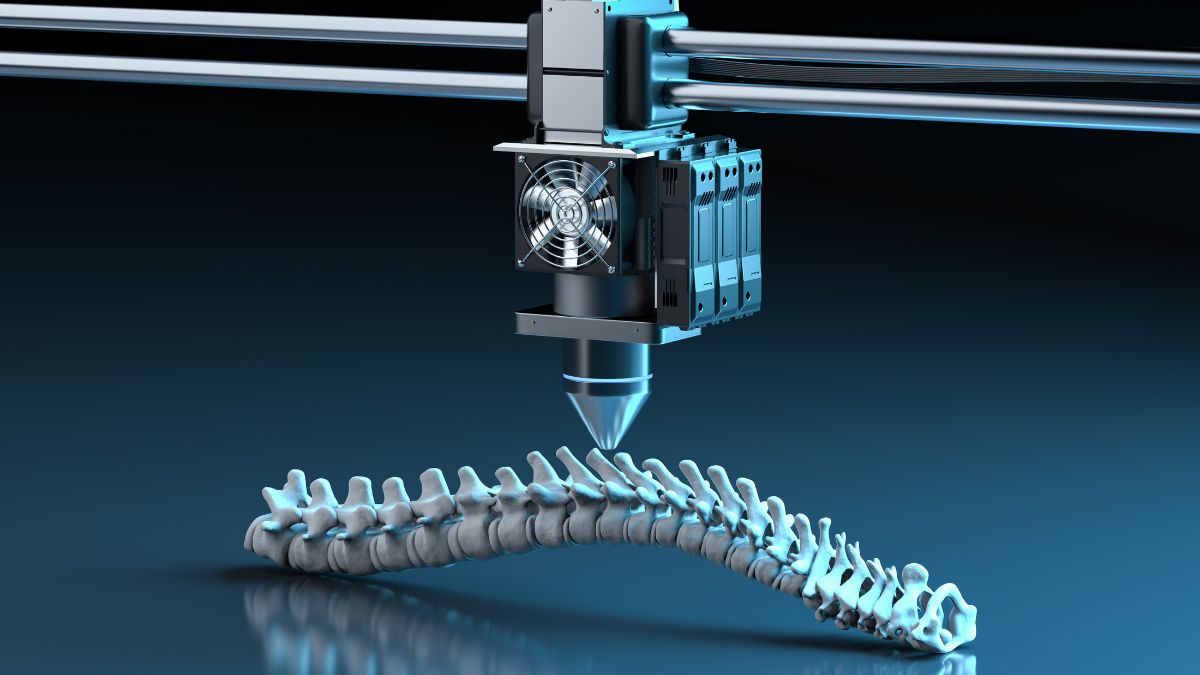

- Material flexibility: Depending on the printer and technology used, prototypes can be created with rigid, flexible, or even biocompatible materials, adapting to the needs of different sectors.

- Early validation: Access to physical prototypes in the early stages of development enables functional, ergonomic, and aesthetic testing, detecting problems before moving into mass production.

- Personalization and adaptability: SUnique or customized prototypes can be created without the need to modify complex industrial processes.

Featured Apps

- Automotive Industry: Creation of components and parts for aerodynamic or structural testing. Rapid iterations allow for specific adjustments to vehicle designs.

- Electronic product development: Custom housings, circuit boards, and structural parts can be manufactured rapidly, facilitating the assembly of functional prototypes.

- Health and biomedicine: The development of personalized prosthetics and medical devices benefits greatly from this technology, as it allows for the manufacture of unique parts tailored to each patient.

- Architecture and urban design: Models a esa cove of buildings and urbanizations help to visualize construction projects in a tangible way.

How to optimize the prototyping process?

To achieve maximum performance, it is essential to follow these steps:

- Efficient design: Take full advantage of the capabilities of 3D printing designing parts optimized for manufacturing.

- Material selection: Consider the mechanical and aesthetic properties that the prototype must meet.

- Appropriate post-processing: Polishing, sanding or heat treatment may be necessary to obtain the desired finish.

- Testing and feedback: Rperforms early testing to identify adjustments before producing final versions.

Don't have a prototype model? We'll do it for you!

If you don't have it 3D model of your project, we create it for you. We have extensive experience in rapid prototyping using advanced technologies such as CNC, SLA, SLS, and FDM. We also work with high-quality materials such as fiberglass, carbon fiber, and silicone molds, ensuring precise and customized results.

Our team of experts can advise you on the best technology for your specific needs, ensuring a prototype with optimal functionality and finish. We focus on maintaining confidentiality in each project and have over 18 years of experience developing complex prototypes, employing cutting-edge techniques such as FDM, SLA, SLS, MJF, CNC, and LC. If you need customized prototypes with precision and speed, we can help!

Success stories

Companies like Tesla and Boeing have implemented rapid prototyping to reduce the development time of critical parts. In the medical sector, startups are designing customized assistive devices in a matter of hours, improving patients' quality of life.

Companies that adopt this technology will be better prepared to face the challenges of today's marketplace, where the ability to innovate quickly makes all the difference.

Explore rapid prototyping options and 3D printing that we can offer you at Innou!