All the secrets of 3D modeling

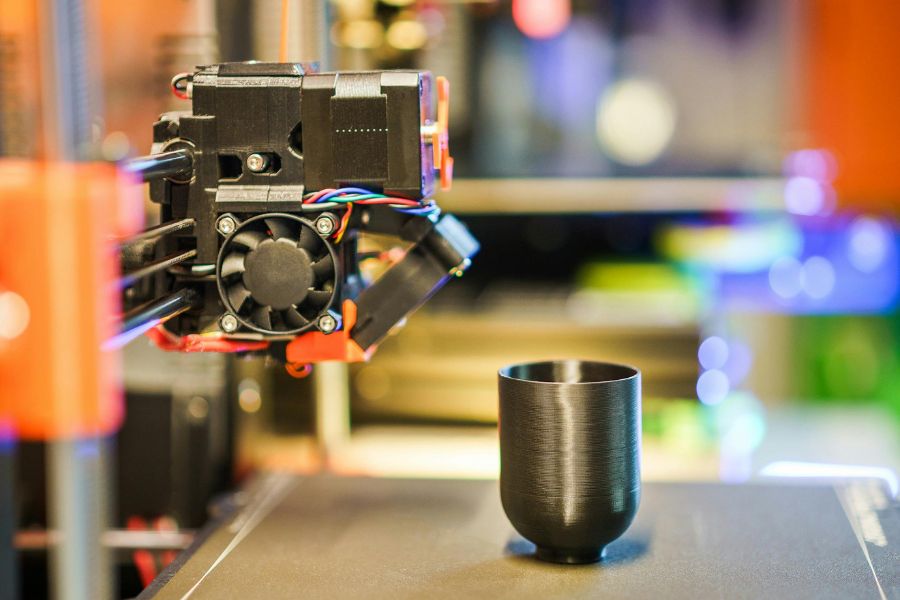

The 3D printing It has revolutionized the way we design and produce objects, opening up possibilities that previously seemed unimaginable. This process has become an essential tool in various sectors. However, when the goal is to achieve maximum realism, the key lies not only in the quality of the printer, but in the meticulous attention to detail in the production phase. 3D modeling and in the use of specialized tools.

He modeling is the heart of the process 3D printing. A realistic piece begins in the software, where every aspect is designed, from the textures and curvatures to the small details that add authenticity. 3D modeling tools They allow you to create digital files with such a high level of detail that the printer can replicate them exactly.

Advanced rapid prototyping technology

At Innou, we use specialized programs and advanced tools for modeling and 3D printing, to shape parts and simulate their behavior in the real world, which helps to anticipate potential problems before printing.

We use advanced technologies rapid prototyping such as CNC, SLA, SLS and FDM:

- CNC (Computer Numerical Control): Ideal for parts that require high precision in machining. This technology allows working with a wide variety of materials, from plastics to metals, ensuring impeccable finishes and consistency in every detail.

- SLA (Stereolithography): Mainly used to obtain parts with an extremely high level of detail and smooth surfaces. It is perfect for complex designs that require professional finishes, such as product prototypes or visual models for presentations.

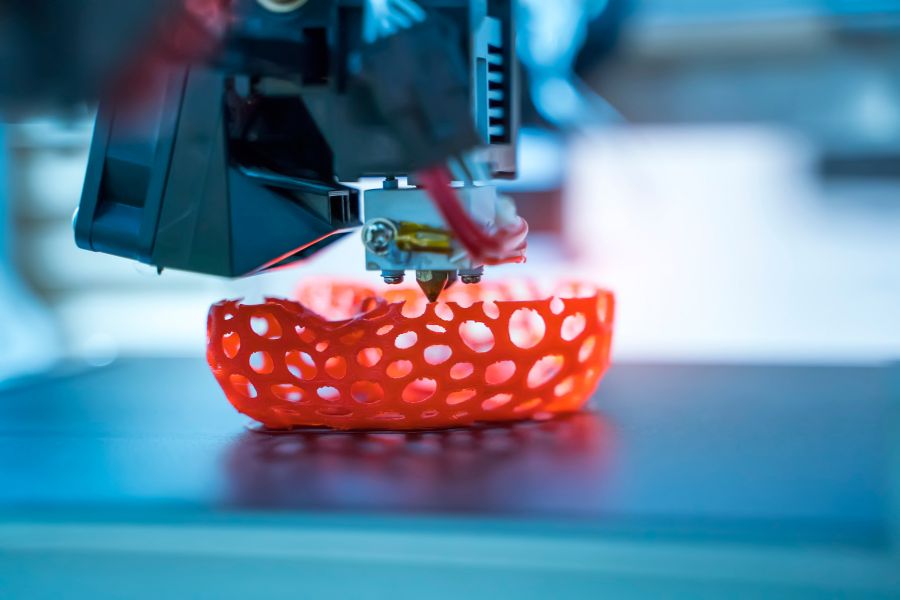

- SLS (Selective Laser Sintering): Especially suitable for projects that demand strength and durability. This technology uses lasers to sinter powdered materials, such as polymers, creating solid and functional structures without the need for supports.

- FDM (Fused Deposition Modeling): One of the most versatile and accessible techniques, ideal for functional prototypes and custom parts. It is widely used in the manufacture of mechanical components and products that require specific strength or flexibility properties.

The integration of these technologies into our workflow for the 3D printing allows us to offer fast, precise solutions adapted to any type of requirement, whether in the creation of initial prototypes, functional tests or limited productions. We have a solid experience working with materials such as fiberglass, carbon fiber and silicone molds. We offer you personalized advice to choose the most appropriate technology to develop your products. 3D projects successfully.

What level of detail can we achieve with 3D printing?

The level of detail in a model 3D printing can make the difference between a basic print and a piece that is indistinguishable from a real object. To achieve maximum realism, it is important to take into account several factors:

- Model resolution: The more polygons or data points your design has, the smoother the printed result will be.

- Texturing: Applying realistic textures, such as rough edges, metallic finishes or natural patterns, adds an extra level of authenticity

- Dimensional accuracy: In functional projects, measurements must be exact for parts to fit or function properly.

- Post-processing: Techniques such as sanding, painting or applying special finishes can transform a basic print into a masterpiece.

Types of prototypes that can be made with 3D printing

- Industrial prototypes; Companies turn to the 3D printing to create prototypes that simulate final products. These must be visually identical to the finished version, especially in sectors such as automotive or technology.

- Architectural modeling; Architectural studios use the 3D printing to make detailed models of buildings, including realistic textures of materials such as stone, glass or wood.

- Artistic reproductions; In the art world, 3D printing makes it possible to recreate sculptures, figures or decorative pieces with a level of detail that rivals artisanal work.

- Custom apparel and accessories; Fashion and jewelry designers use technology to create unique and realistic pieces that stand out for their detail and precision.

- Models for film and video games; The creation of characters, sets or props for audiovisual productions depends on prints that are faithful to the digital design, both in form and texture.

- Personalized medicine; In the medical field, precise anatomical replicas are manufactured for surgical simulations or customized prostheses that require extreme realism to be functional.

The challenge of realism: combining design and technology

Achieving hyper-realistic parts with 3D printing is no easy task. It involves an iterative process where design, material, printing technology and post-processing work together. This approach not only guarantees high-quality results, but also positions 3D printing as an indispensable tool for projects where attention to detail makes the difference.

Realism and detail, the future of 3D printing

The 3D printing It is not just a technique, but an art that combines creativity and technology. In projects where realism is essential, success depends on dedication to detail from the modeling phase to the final finish. By using advanced tools and innovative materials, we can create pieces that not only fulfill their function, but also impress with their authenticity.

If you are considering a project 3D printing, remember: detail is not a luxury, but a necessity to achieve maximum realism and functionality.