A technology with many possibilities

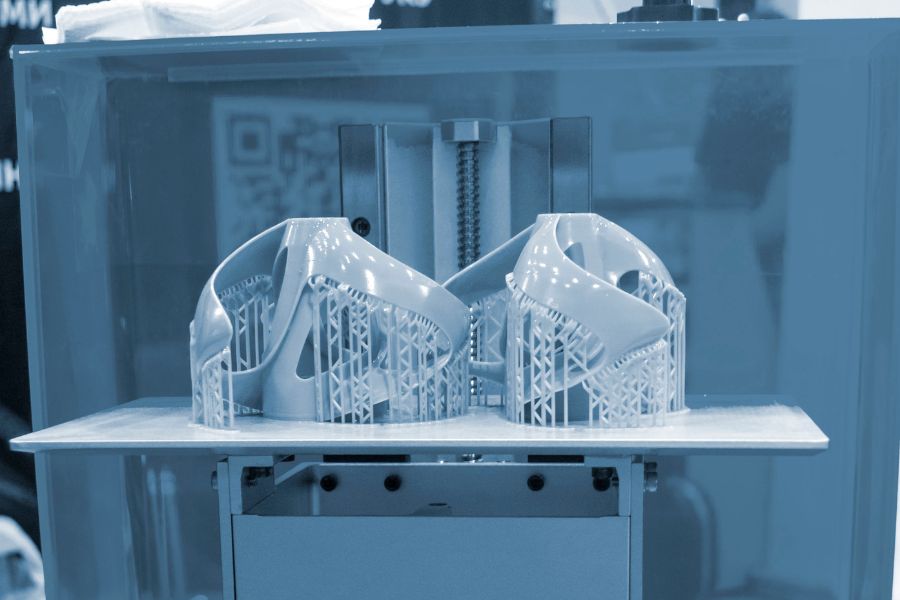

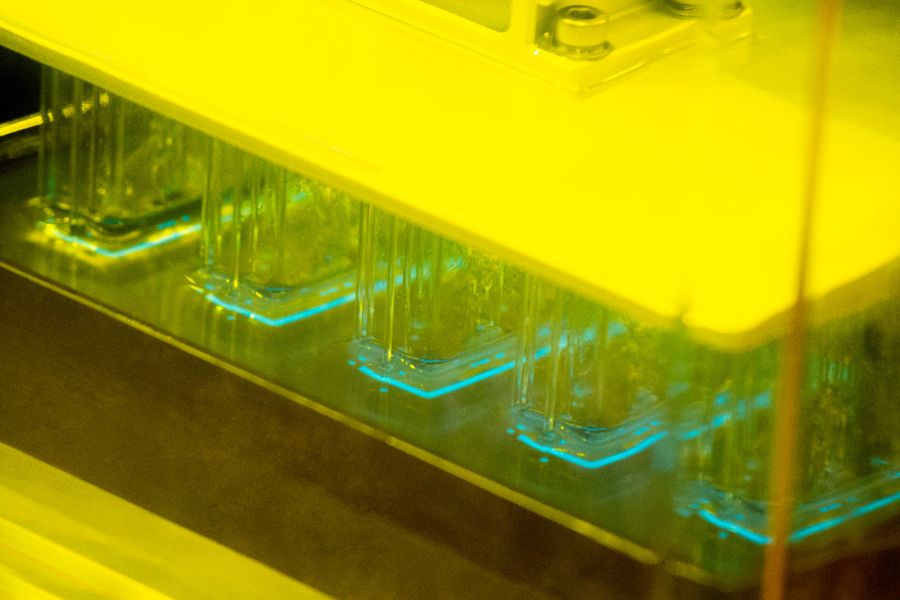

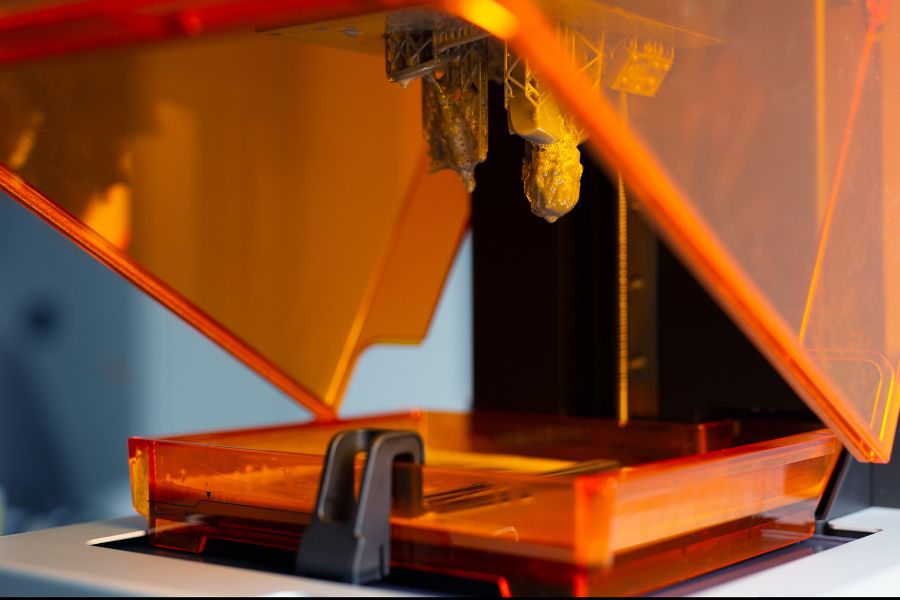

The 3D printing has transformed the way companies design, develop and produce products. Among the various technologies available, stereolithography (SLA) stands out as one of the most precise and versatile options. This method, based on the solidification of liquid resin using laser light, not only offers high-quality results, but also presents significant advantages in terms of speed, efficiency and flexibility in the choice of materials. Stereolithography was one of the first 3D printing technologies developed and remains one of the most advanced. This process uses an ultraviolet laser to solidify successive layers of photopolymeric liquid resin, creating objects with a level of detail superior to other techniques. These are some of the main features of this technology for 3D printing:

- High precision and quality of detail: It is capable of producing parts with very fine resolutions, ideal for complex designs and functional prototypes.

- Fast printing speed: Compared with other technologies, SLA can produce high-quality parts in less time.

- Variety of materials: The liquid resins used in SLA offer a wide range of properties, such as mechanical strength, flexibility or transparency, adapting to various needs.

- Savings and efficiency in the use of materials: Technology allows the use of resin to be optimized, reducing waste and costs.

What applications does SLA 3D printing offer for product design and development?

The 3D printing with SLA technology It is a powerful and versatile solution for the product development in different industries. Its precision, speed and the variety of materials available make it an indispensable tool for companies seeking to innovate and optimize their processes. These are some of the sectors in which this technology is used. 3D printing for the product development and design:

1. Product development and prototypes: In the design of new products, SLA allows for the creation of functional prototypes with precise details that simulate the final characteristics of the product. This speeds up the iteration process and reduces the costs associated with development.

2. Medical and Dental Sector: SLA 3D printing has revolutionized the medical field, especially in dentistry. It is used to manufacture dental models, aligners, temporary crowns, and customized surgical devices. Its ability to work with biocompatible resins ensures that the parts are safe for clinical use.

3. Jewelry: SLA precision is ideal for creating detailed master models used in jewelry casting. Designers can produce intricate pieces quickly and accurately, reducing design and manufacturing times.

4. Automotive and Aerospace: In these sectors, SLA is used to manufacture high-precision prototypes, functional components and custom tooling. The strength of the resins allows for fit and functionality testing before moving into mass production.

5. Architectural and artistic modeling: SLA technology enables architects and artists to create detailed models that faithfully represent their designs. This includes models of buildings, sculptures and complex decorative objects.

6. Consumer Electronics: From custom housings to functional parts for electronic devices, SLA is a key tool for innovating in consumer product design.

From prototypes From manufacturing to finished products, SLA enables designers and manufacturers to transform their ideas into reality with unsurpassed detail and quality. In a world where speed and customization are key, this technology continues to open doors to new possibilities and applications.

Rapid prototyping that accelerates development cycles and optimizes creative and productive processes

He rapid prototyping It is one of the most common applications of the 3D printing SLA, especially in early stages of product development. A representative case is found in the automotive industry, where engineers use SLA prototypes to test mechanical parts and adjust designs before manufacturing them in final materials.

Prototypes created with SLA technology have a level of detail and precision that allows them to faithfully simulate the performance of the final product. This feature is essential for identifying and correcting design problems at early stages, preventing them from becoming costly errors during production. In addition, thanks to reduced printing times and the ability to generate multiple iterations quickly, SLA technology significantly accelerates development cycles, optimizing creative and productive processes.