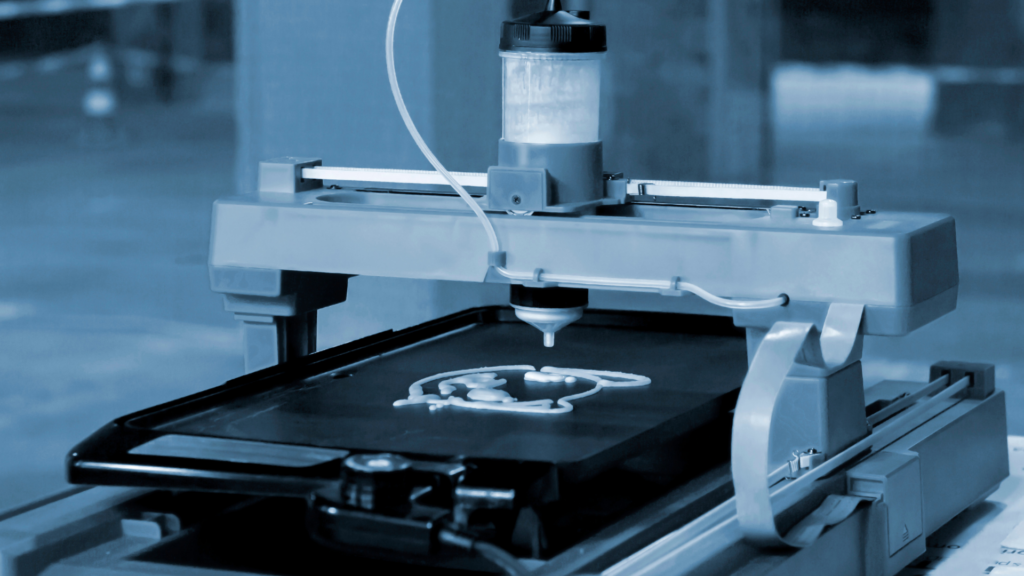

The 3D prototypes have transformed product development, enabling rapid and accurate design validation before mass production. Thanks to this technology, it's possible to detect errors, make adjustments, and improve efficiency at every stage of the manufacturing process. That's why at Innou we offer 3D printing and modeling services for the creation of functional prototypes, reducing development times and costs. From industrial parts to architectural models and custom components, we work with a variety of technologies and materials to ensure the best solution for each project. We adapt to the specific needs of each client, providing high-quality prototypes that meet the desired technical and aesthetic requirements.

3D prototypes

The importance of 3D prototypes in the product creation process

Advantages of 3D prototypes in product development

The manufacture of 3D prototypes allows for the evaluation of shapes, dimensions, and functionality before moving into series production. Thanks to our experience in additive design and manufacturing, our customers can optimize their processes and minimize errors in the development of new products. Some of the main advantages of 3D prototypes are:

- Reduction of development times by detecting improvements immediately.

- Savings in production costs by avoiding expensive molds and tools.

- Total customization, adapting to the needs of each project.

- Functional and ergonomic validation before final manufacturing.

What printing technologies do we use for 3D prototypes?

For the manufacture of 3D prototypesWe use a variety of printing technologies that guarantee the quality and precision of each piece. These include:

- FDM (Fused Deposition Modeling): ideal for functional prototypes and mechanical parts.

- SLA (Stereolithography): high precision and excellent surface finish for detailed prototypes.

- SLS (Selective Laser Sintering): perfect for strong pieces without the need for supports.

- MJF (Multi Jet Fusion): advanced printing for high-performance prototypes.

In our 3D printing company we work in:

• Creation of custom 3D models from ideas or sketches.

• Design optimization to improve strength and reduce material.

• Manufacturing of industrial, artistic and medical components.

• Post-processing of parts to improve the appearance and final finish of the product.

Contact Innou to create your 3D prototypes

With years of experience in the industry, we specialize in offering customized solutions for the creation of 3D prototypes across multiple sectors, including automotive, engineering, architecture, and medicine. Our team will provide you with personalized attention to tailor each design to your specific needs, ensuring optimal results. We work with a wide variety of materials, ranging from plastics to resins and advanced composites, enabling the manufacture of prototypes with diverse properties and applications.

We are committed to fast and efficient delivery, optimizing production times without compromising quality. We also offer expert advice at every stage of the process, from conceptualization to final manufacturing. If you are looking for the best solution in 3D prototypes, contact us and discover how we can help you turn your idea into a high-quality, functional, physical model.

Talk later?

We are here to help you, send us your details and we will contact you to make what you have in mind a reality.

- Novell 36, Bajos 08028 Barcelona, Spain

- info@innou.eu

- +34 93 411 9393